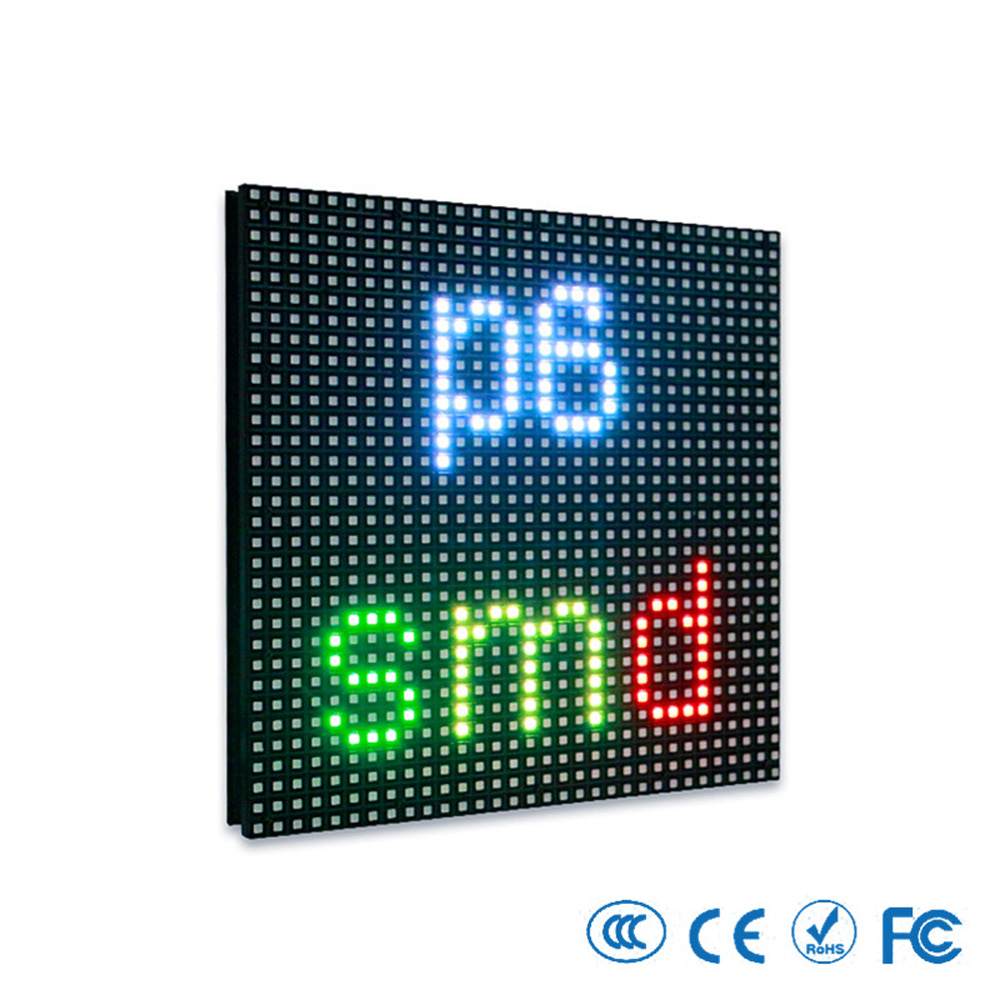

Outdoor P6 LED Display Module

For custom orders and bulk discounts, contact our sales team

$8.00

II. Installation Guide

1. Frame Design

Installation Methods: Magnetic/snap-in installation; supports floor-standing, wall-mounted, or suspended mounting.

Frame Material: Recommend hot-dipped galvanized steel structure (thickness ≥2mm), corrosion-resistant treatment required at welding joints.

Flatness Requirement: Surface flatness deviation ≤2mm/m² after module assembly.

2. Waterproofing & Cooling

Waterproofing Design:

Apply waterproof sealant (e.g., Dow Corning 732 silicone) around module edges.

Reserve drainage holes (diameter ≥10mm) at the bottom of the cabinet.

Recommended Dual Sealing: Module mask + cabinet waterproof layer.

Cooling Solutions:

Forced Air Cooling: Axial fan (airflow ≥1200m³/h installed on the upper back of the cabinet).

Built-in Air Conditioner: Single 2P AC controls ≤15m² screen area (recommended for ambient temperatures >40°C).

3. Power & Signal Wiring

Power Connection:

Each module requires independent DC 5V power supply; power cable specification ≥2.5mm² (copper core).

Main power line: Three-phase five-wire system (L1/L2/L3/N/PE); grounding resistance ≤3Ω (lightning protection).

Signal Connection:

Use NovaStar-specific HUB75 ribbon cables to connect modules and receiving cards. Ensure secure connections.

Transmission Distance:

Cat6 Ethernet: ≤100m (no repeater).

Single-mode fiber: ≤20km (recommended for long distances).

III. Commissioning with NovaStar

1. Control System Setup

Recommended Hardware:

Main Controller: NovaLCT-T Pro / NovaPro HD

Receiving Card: NovaA8-A / NovaDVI-HD

Transmission Protocol: HUB75 signal + Cat6 Ethernet / single-mode fiber

2. Software Configuration

Step 1: Resolution Matching

Open NovaLCT/NovaStudio and set the sender card output resolution to match the total LED screen resolution.

Example: For a 960×960 screen assembled from 192×192 modules, set the resolution to 960×960.

Step 2: Refresh Rate Setting

NovaStar recommends a refresh rate ≥3840Hz (ensures flicker-free display).

Step 3: Color Calibration

Perform pixel-by-pixel calibration using NovaStudio to ensure ΔE ≤2.5.

Step 4: Brightness Adjustment

Adjust brightness automatically or manually based on ambient light (supports 0–100 levels).

3. Commissioning Steps

Power-off Inspection:

Connect all power and signal cables with power off; use a multimeter to test for short circuits.

Upload Configuration:

Upload resolution, refresh rate, and color gamut settings to the NovaStar main controller.

Power-on Test:

Display "Red/Green/Blue/White" test patterns to check dead pixel rate (<0.0002‰).

Monitor internal temperature (≤45°C) and power status via NovaStudio.

Calibration Optimization:

Run NovaStudio to calibrate brightness uniformity (≥95%).

Adjust color temperature to target value (e.g., 6500K standard white balance).

IV. Common Issues & Solutions

Issue | Cause | NovaStar Solution |

|---|---|---|

Black Screen on Part of Display | Loose power cables or disconnected HUB75 signal line | Use NovaStar diagnostic tools to test power/signal integrity; replace damaged cables |

Color Unevenness | Uncalibrated module color or ambient light interference | Perform pixel-level color calibration via NovaStudio (ΔE ≤2.5) |

Signal Delay | Incorrect resolution settings or insufficient transmission bandwidth | Adjust NovaLCT-T Pro output resolution; upgrade to single-mode fiber |

High Temperature Alarm | Cooling system failure or clogged fan filter | Check fan status via NovaStar monitoring software (internal temperature ≤45°C) |

Dead Pixels Exceeding 0.0002‰ | Mechanical damage during transport/installation | Replace damaged modules; locate faults using NovaStar diagnostic tools |

V. Maintenance & Care

Routine Maintenance

Clean module surfaces with a soft cloth and anhydrous alcohol to prevent dust buildup and heat dissipation issues.

Use NovaStar monitoring software to check power/signal status weekly.

Annual Inspection

Test brightness uniformity (≥95%) and color consistency (ΔE ≤2.5).

Inspect waterproof seals and drainage hole functionality (prior to rainy season).

Long-term Storage

Store in humidity <60%, temperature 0°C–30°C, away from direct sunlight.

Power on modules every quarter for 1 hour to prevent capacitor aging.

Applications

Suitable for outdoor advertising, stadiums, stage performances, and transportation hubs. Integrate with NovaStar control systems for high-definition video playback (supports 2K/4K), multi-zone displays, and remote monitoring.

I. Basic Specifications of the Outdoor P6 LED Module (192×192mm)

Category | Parameter | Value |

|---|---|---|

Physical Features | Module Size | 192mm × 192mm |

Pixel Pitch | 6mm | |

Resolution | 32 (Width) × 32 (Height) = 1,024 pixels | |

Pixel Density | 27,778 dots/m² | |

Pixel Composition | 1R1G1B (Full Color) | |

Module Weight | ≤1.8kg | |

Display Performance | Brightness | ≥5,000 cd/m² (White Balance Condition) |

Color Temperature | 2,000K–9,500K Adjustable (Supports Calibration) | |

Refresh Rate | ≥1,920Hz–3,840Hz (Recommended by NovaStar ≥1,920Hz) | |

Gray Scale Level | 16bit (65,536 Levels) | |

Viewing Angle | Horizontal 140°, Vertical 120° | |

Electrical Specifications | Operating Voltage | DC 5V ±5% |

Power Consumption | Average 30W/Module, Peak 50W/Module | |

Protection Rating | IP65 (Outdoor Dustproof & Waterproof) | |

Operating Temperature | -20°C to +50°C |

Notes

Pixel Configuration:

Each pixel consists of 1 Red (R), 1 Green (G), and 1 Blue (B) LED (Full Color).

Brightness Uniformity:

Brightness uniformity ≥95% after factory calibration.

Color Consistency:

Color deviation ΔE ≤2.5 (calibrated with NovaStar software).

Environmental Compliance:

Designed for outdoor use with IP65 protection rating and wide operating temperature range.

Global application cases

The video content is based on actual customer project site feedback and real-time factory production footage, truly recording the entire process of each screen from manufacturing to lighting.